Needle Roller Bearings are considered the most preferred choice of all the other kinds of bearings. The needle roller bearings are different from ordinary roller bearings and ball bearings in that, they use little cylindrical rollers (needles) that are almost four times in length than their diameter, thus covering more surface area than, say, a ball bearing, and resulting in being more efficient for supporting heavier load and reducing friction better as well as preventing excessive heating up of the mechanism. Needle Bearings come in various designs and are used in a variety of automotive and industrial purposes. These are manufactured using steel, aluminum as well as plastic castings. Needle Roller Exporters of India export Needle Rollers to United States of America, Japan, Indonesia, United Kingdom, Peru, Egypt, Thailand, Bangladesh, Italy, United Arab Emirates, Germany and other countries. United States of America has been recorded as one of the leading importers of Needle Rollers manufactured in India.

1. The Various Designs that the Needle Roller Bearings come in

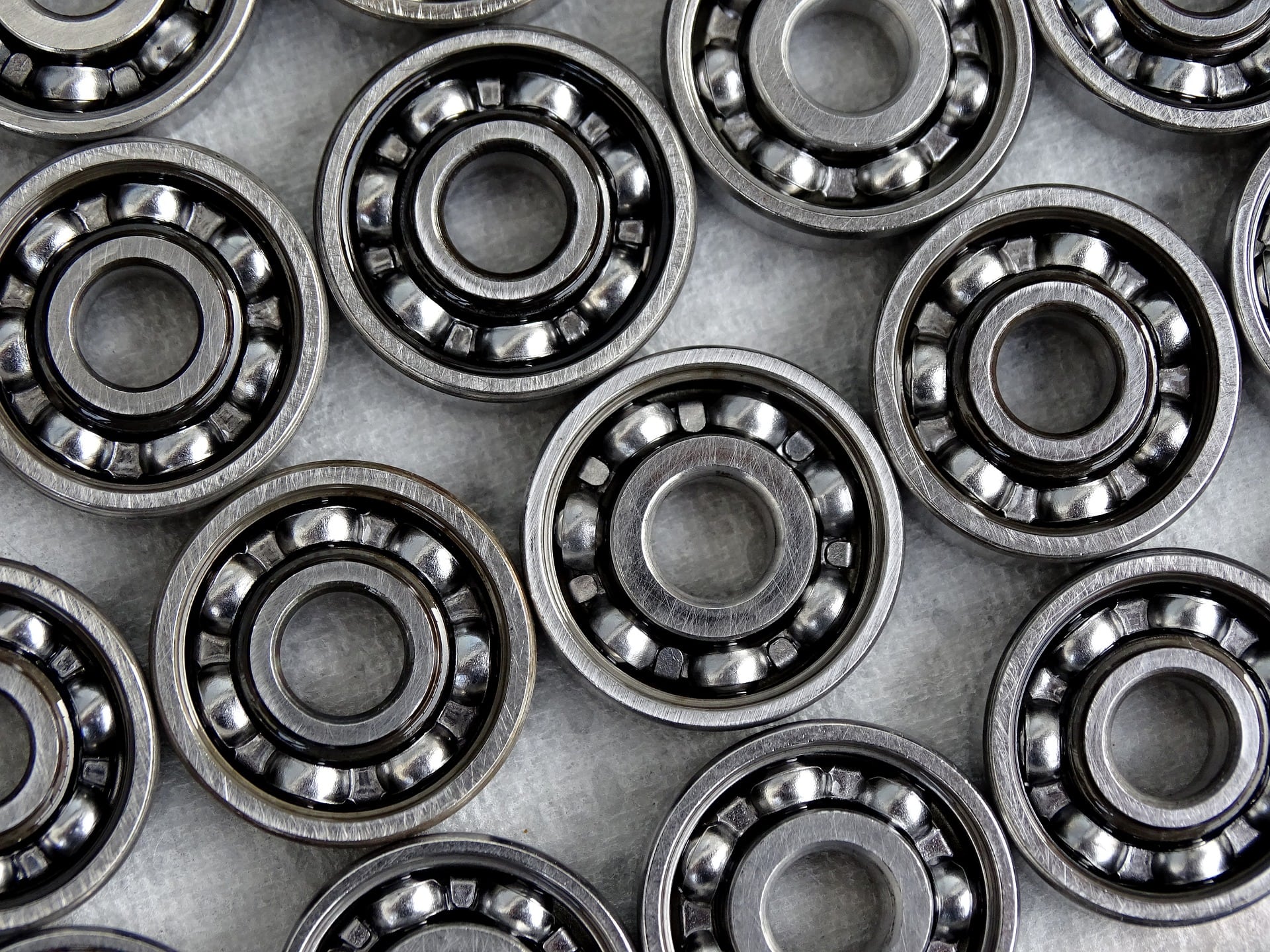

The basic constitution of a needle roller bearing comprises of an inner race or shaft, a needle cage that holds and aligns the needle rollers, the rollers themselves and finally, an outer race. There are several kinds of designs that needle bearings are manufactured in and the utility of each depends on the demand of the apparatus it will be required in. There are two main types and several other sub-types of needle roller bearings manufactured. The two main kinds are the full-complement of loose-needle bearings (which were used majorly in the past, before the caged needle roller bearings were invented, over 60 years ago, in 1949), and the caged needle roller bearings. The full complement needle bearings have no retainers and are comparatively economical, but come with a couple of major flaws: in faster paced machinery, the loose-needle bearings have a tendency to skew or misalign, thereby raising the frictional heat; in addition, when the clearance space is tight, the bearings lock or get stuck too often. The caged needle bearings, have a complex set up with multiple needle rollers universally spaced in a cage, rotating axially, thus overcoming all the above shortcomings, with the added advantage of producing superior lubrication capability and being three times quicker.

The sub-types include drawn cup, precision race, thrust, heavy duty, air-frame and track needle roller bearings. The heavy duty bearings, as the name suggests, have substantial outer rings that work better with heavier and hardened machines, and have extreme load capacities. The drawn cup needle bearings have both loose needle as well as caged needle models. The loose needle drawn cup bearing has rollers with spherical-ends, with an outer raceway, which increases its load capacity, whereas, the caged needle drawn cup bearings have retainers which has relatively lesser load capacity but have higher speed power and reduce the chance of misalignment.

2. Applications of Needle Roller Bearings

The needle roller bearings have major applications in the automotive and industrial spheres, like automotive transmissions, smaller vehicles, tools motors and engines, aircraft controls, farm equipments, gear pumps, hydraulic pumps, constructions tools and apparatus, and almost in any and every rotating machinery.

The various designs of needle roller bearings are still under constant improvement and development to meet the newer demands of the growing industries all over the world, while its application in diverse spheres increase manifold, simultaneously. Among the Needle Roller Exporters of India, the export business in Noida are reported to be one of the largest, followed by Gurgaon and Delhi respectively.